The Plate And Tube Integrated Laser Cutting Machine Advantages

What are the advantages and characteristics of the plate and tube integrated laser cutting machine compared with the laser tube cutting machine?

Now many laser cutting machine users need to cut plates and pipes in actual production, and the integrated laser cutting machine for plates and tubes was born! In production, is it better to use a plate and tube integrated laser cutting machine or a laser tube cutting machine?

First of all, the cutting materials of the two are not exactly the same. Laser pipe cutting machine is mainly used for cutting various pipes, suitable for all kinds of round pipes, square pipes, rectangular pipes, U-shaped pipes, special-shaped pipes, etc. The integrated laser cutting machine for plates and pipes can cut plates and pipes , one machine with multiple functions, reducing floor space and saving input cost.

Secondly, the functional characteristics of the two are different, and each has its own advantages.

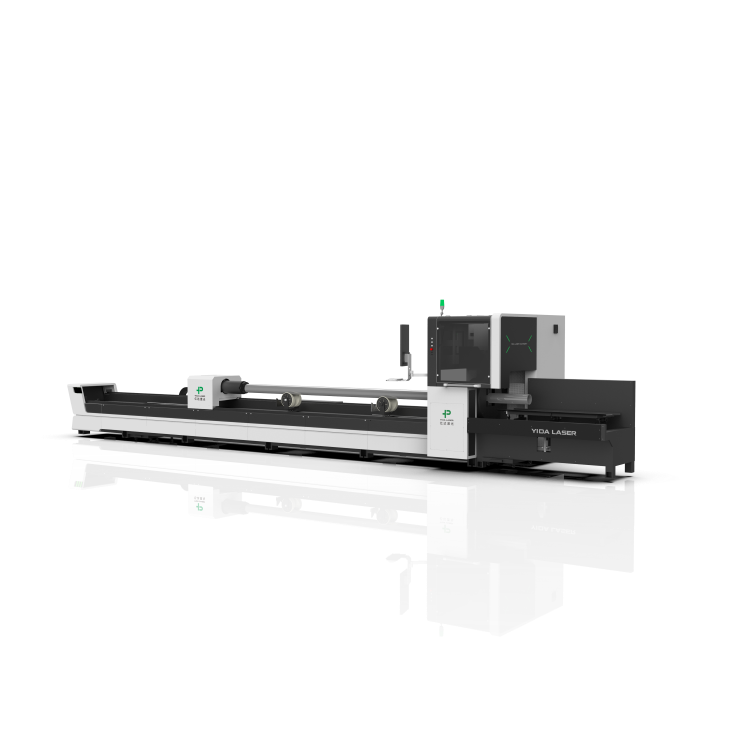

Advantages of laser pipe cutting machine:

1. Multiple different directions can be cut on the main pipe. Cylindrical intersecting holes with different diameters satisfy the condition that the axis of the branch pipe intersects with the main axis eccentrically and non-eccentrically.

2. The end of the cylindrical intersection line can be intercepted at the end of the branch pipe to meet the conditions of eccentric and non-eccentric vertical crossing and oblique crossing between the branch pipe axis and the main shaft.

3. It can cut the beveled end face of the end of the round pipe. Square and waisted holes can be cut in round tubing.

4. It can cut various graphics on the surface of the square tube.

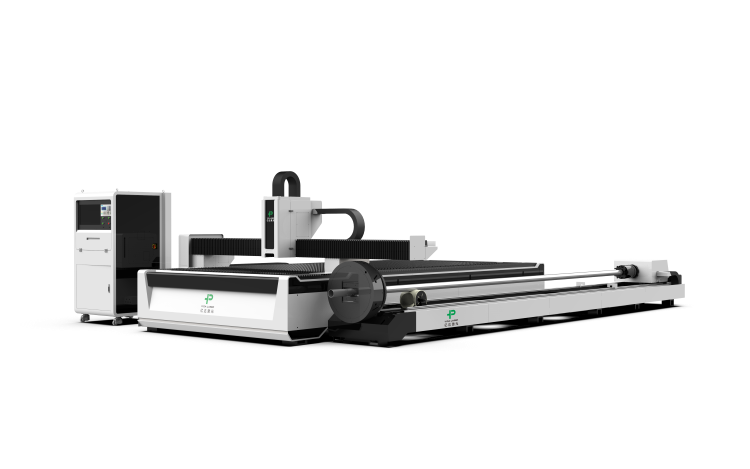

Advantages of plate and tube integrated laser cutting machine:

1. The plate and tube integrated laser cutting machine is equipped with a plate and tube double cutting function. One piece of equipment completes multiple processes, which can not only reduce the area of the equipment, but also reduce the cost investment of the equipment.

2. Laser processing adopts a unified fixture tool, and the entire processing process is completed by programming software. Using laser cutting to process products, the cutting part is smooth and the cutting seam is small. The finished workpiece has no deformation and can directly enter the next process.

3. The processing speed of the plate and tube integrated laser cutting machine is dozens of times that of the traditional processing method, which can realize batch processing. The processing process can be cut at any time. The conversion of cutting tubes greatly improves the production efficiency.

Summary: The plate and tube integrated laser cutting machine has advantages in cutting; the laser tube cutting machine cannot cut the plate, but the tube cutting precision is high and the process engraving is strong, which can meet the requirements of many cutting tubes. If there are both pipes and plates in metal processing, and the pipe processing volume is relatively small, the plate-tube integrated laser cutting machine is more suitable. If the pipe processing volume is large, it is recommended to purchase a laser pipe cutting machine. After understanding, you can choose according to your needs!