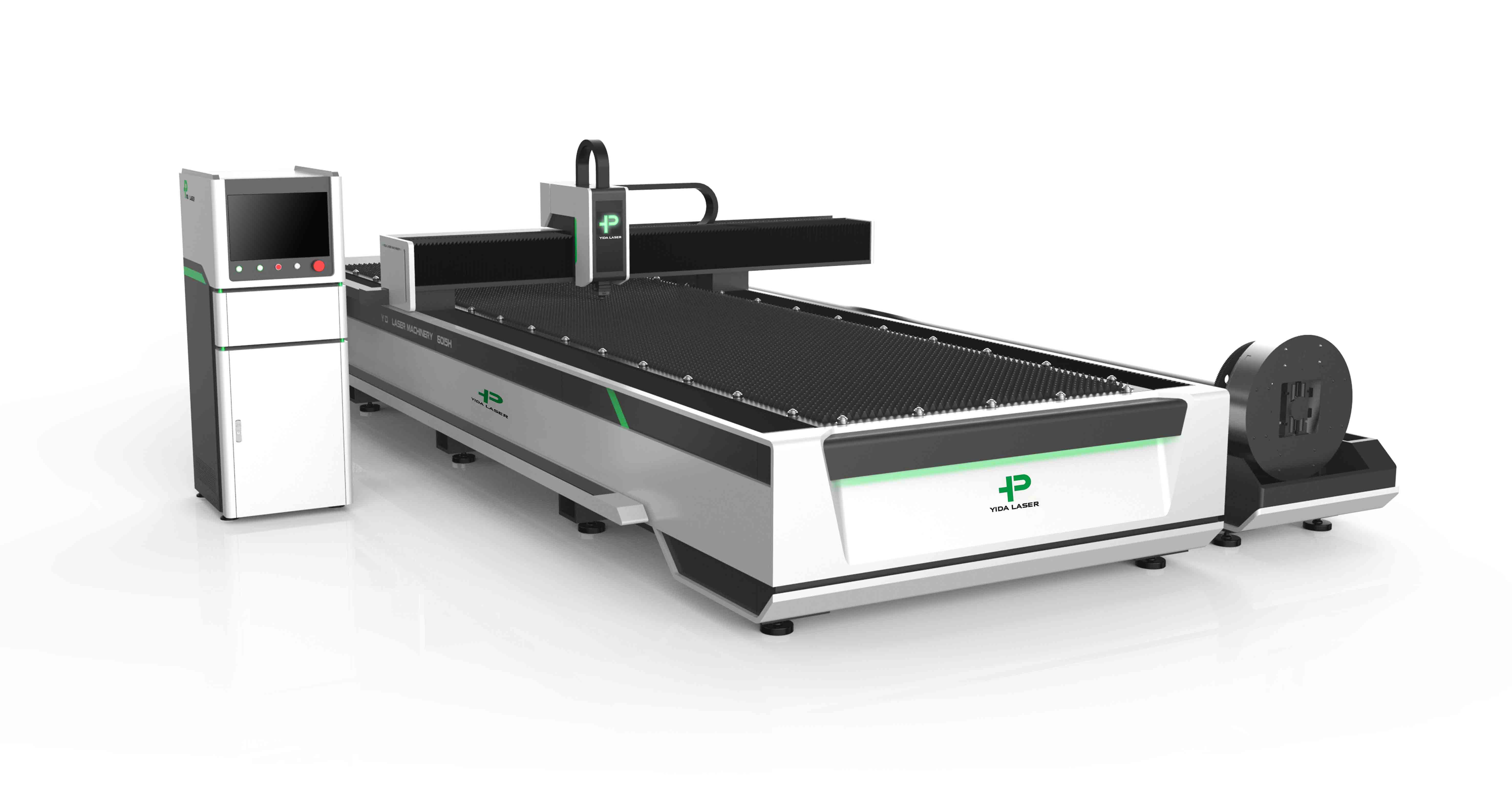

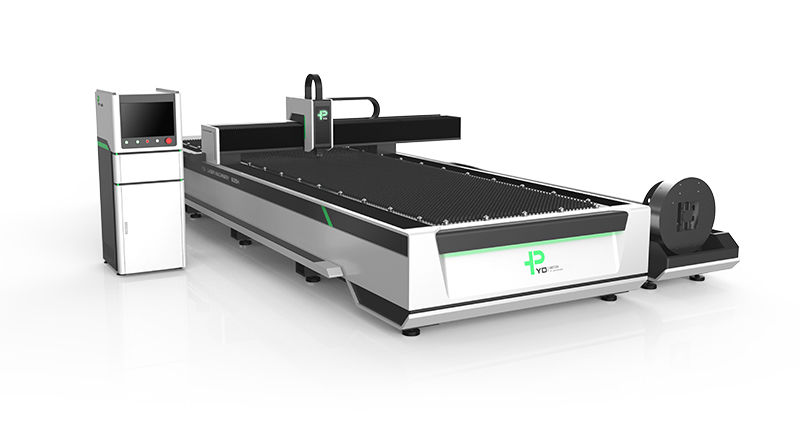

Sheet and Tube Laser Cutting Machine

CM One machine for two purposes,

CM A variety of pipes with high fitsaving cost.

CM Cast aluminum beam with good

CM Welding bed, with higher precision dynamic performance and high stability. and good stability. (optional casting)

Sheet and Tube laser cutting Machine Supplier For Metal

Sheet and Tube laser cutting machine,Laser Cutting Machine Supplier,Laser Cutting Machine for metal

Tube Laser Cutting Machine price,tube laser cutting machine price in india,tube laser cutting machine for sale

Model CM-Type plate&tube dual-purpose machine

Produt Introduction:

The laser plate and tube all-in-one desktop device is outfitted with extraordinary expert collets and fixtures pipes of distinct shapes and sizes can be processed accurately.

Laser tube reducing is a manufacturing effectivity with high, effective and bendy technology, the operator can alter the layout scheme besides affecting it.

The total product manufacturing process;

The higher benefit is that cease customers can manipulate the manufacturing of brief model or medium model barring make a giant quantity of templates so that you can reply extra rapidly to consumer needs, which does no longer require casting model.

In the metallic processing industry, plate tube built-in laser reducing desktop is greater and extra broadly used.

Many steel processing producers have each the wishes of processing steel plates and metallic pipes.

Plate tube built-in laser reducing computing device is naturally the first choice, which can meet the processing wants of customers, It can additionally keep tools procurement value and use one desktop for a couple of purposes.

The foremost physique of the laser plate and tube all-in-one laptop adopts the welding bed process, which has excessive mechanical strength, notably quick manufacturing cycle, handy to prepare manufacturing and decrease thermal sensitivity.

Advanced technology

The special slicing procedure database can elevate out distinctive wise reducing for distinctive materials, optimize the reducing surface, reduce a wider vary of materials, quicker speed, higher best and decrease cost, and can be utilized to the full insurance of low-power to high-power lasers.

The laser head can robotically keep away from obstacles. The laser head can elevate out excessive dynamic response, predict barriers in boost and shield the laser head to the biggest extent.

Cast aluminum beam is fast. Aluminum alloy has the steel traits of mild weight and sturdy rigidity, which is conducive to high-speed motion in the machining process, and excessive flexibility is conducive to high-speed slicing of a number of pics on the groundwork of excessive precision.

Product Specification:

| Model | CM | |||

| Work Processing Area | 3050mm*1530mm | 4000mm*2000mm | 6100mm*2500mm | 8100mm*2500mm |

| Laser Sources Power | 1000/2000/3000/4000/6000W | |||

| Position Accuracy | ±0.03mm | |||

| X-Y Simultaneous Speed | 100m/min | |||

| Maximum Tube Processing Length | 3000mm 6000mm 9000mm | |||

| Tube Cross Section Shape | Round Tube, Square Tube, Rectangular Tube, Oval Tube, Ob-round Tube, L-Angle Steel, C-Channel Steel and other type of pipes | |||

| Tube Size Range | Round Tube:Φ10-Φ230mm Square Tube:□10-□160mm Oval Tube:170mm≥ Side Length ≥20mm, Outer Diameter≤230mm | |||

Packing:

| Function¶meter List ●standard configuration, ○optional configuration, ×No configuration required | C6M | C4M | C3M | ||

Item | Subitem | ||||

basic parameter | Working area | 6100mm*1524mm | 4000mm*1524mm | 3050mm*1530mm | |

Max. linkage speed | 91m/min | 91m/min | 91m/min | ||

Tube size range | Round tube Φ20-Φ230mm Square tube □20 - □160mm Rectangular tube: 170mm≥Side length≥20mm, Circumscribed circle diameter≤230mm | Round tube Φ20-Φ230mm Square tube □20 - □160mm Rectangular tube: 170mm≥Side length≥20mm, Circumscribed circle diameter≤230mm | Round tube Φ20-Φ230mm Square tube □20 - □160mm Rectangular tube: 170mm≥Side length≥20mm, Circumscribed circle diameter≤230mm | ||

Chuck maximum load | 100kg 16kg/m | 100kg 16kg/m | 100kg 16kg/m | ||

Optical system | Laser source | MAX/IPG | MAX/IPG | MAX/IPG | |

laser head | Ospri | Ospri | Ospri | ||

mechanical system | Machine bed | Mortise-and-tenon type plate welded segmented bed | Mortise-and-tenon type plate welded segmented bed | Mortise-and-tenon type plate welded segmented bed | |

Chuck drive types | Pneumatic chuck | Pneumatic chuck | Pneumatic chuck | ||

Max. length of tube | C-M3/6 tube maximum length is 3m or 6m | C-M3/6 tube maximum length is 3m or 6m | C-M3/6 tube maximum length is 3m or 6m | ||

X-axis、Y-axis、Z-axisServo motor and driver | Japan Fuji/France Schneider | Japan Fuji/France Schneider | Japan Fuji/France Schneider | ||

Linear Rails | Made in Taiwan | Made in Taiwan | Made in Taiwan | ||

Rack | Made in Taiwan | Made in Taiwan | Made in Taiwan | ||

Electrical system | Control system | FSCUT | FSCUT | FSCUT | |

Proportional gas valve | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | ||

O2 Cutting gas control valve | Japan SMC | Japan SMC | Japan SMC | ||

N2 Cutting gas control valve | Japan SMC | Japan SMC | Japan SMC | ||

Intelligent alarm | ● | ● | ● | ||

Acceptable file formats, sheet cutting | G文件、DXF、DWG、PLT、ENG G file、DXF、DWG、PLT、ENG | G文件、DXF、DWG、PLT、ENG G file、DXF、DWG、PLT、ENG | G文件、DXF、DWG、PLT、ENG G file、DXF、DWG、PLT、ENG | ||

Acceptable file formats, pipe/tube cutting | IGS | IGS | IGS | ||

Related News

Submitted successfully

We will contact you as soon as possible