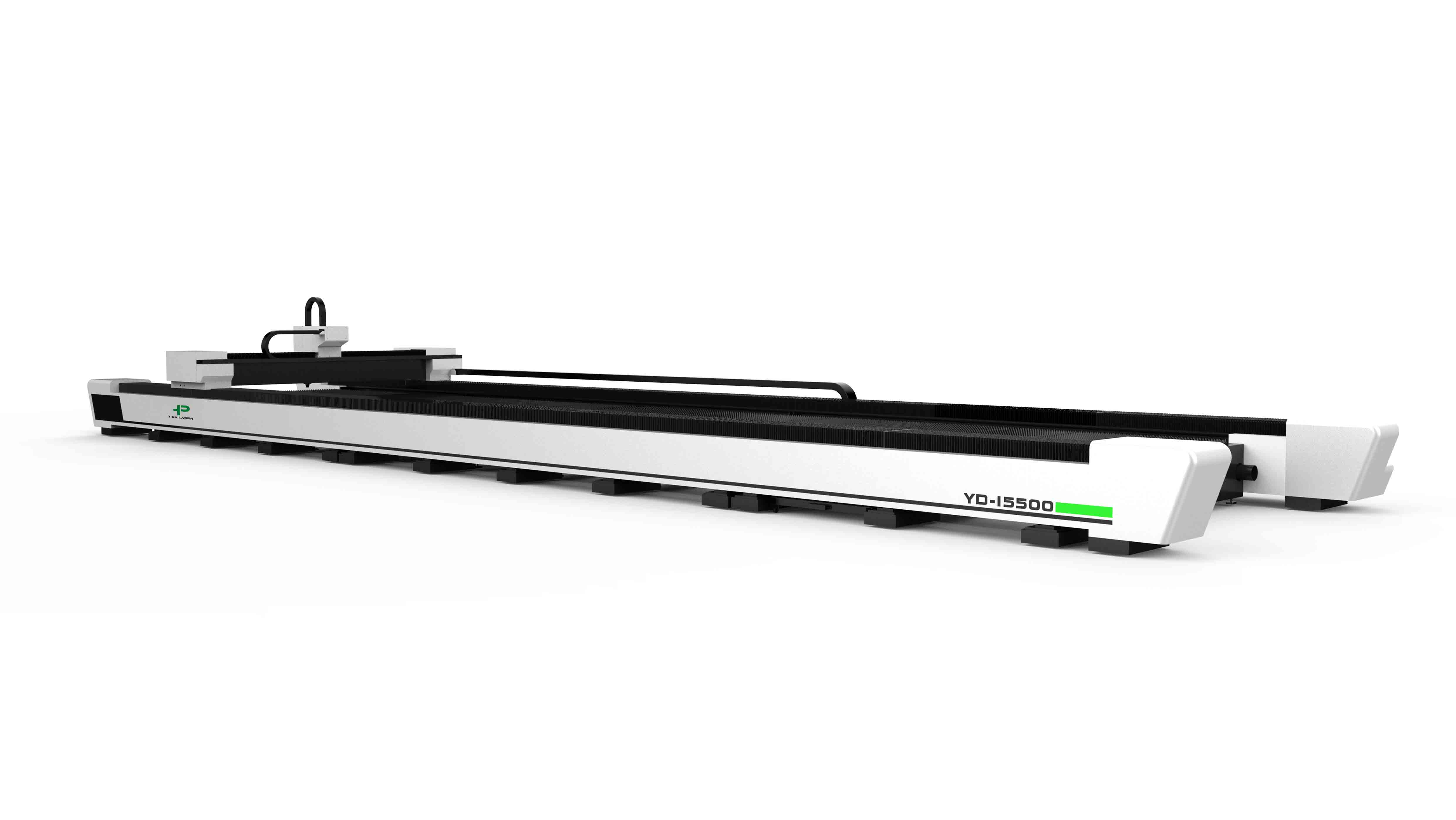

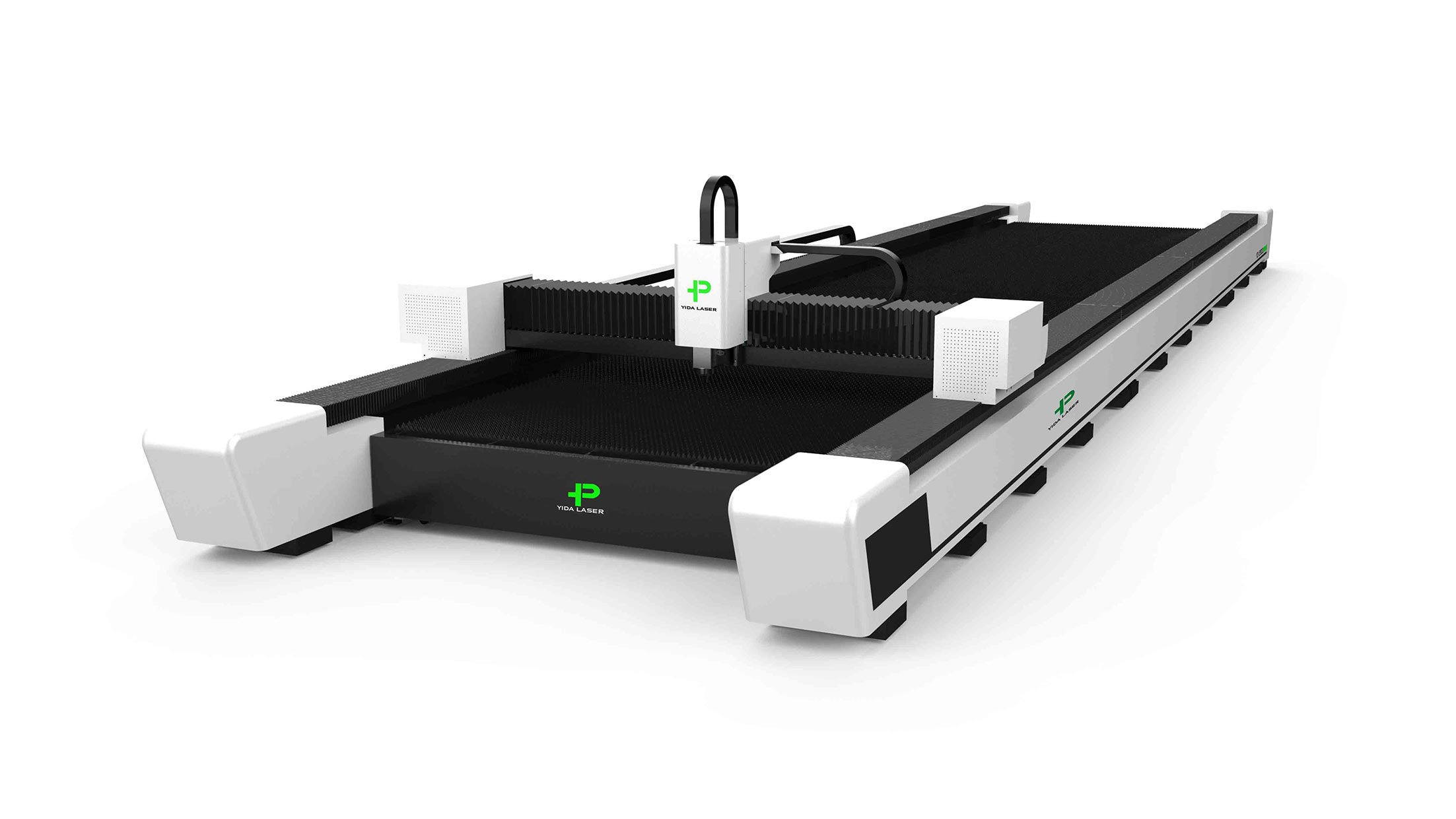

Steel Plate Laser Cutting Machine Sheet Metal Iron

Adopts excessive-power fiber laser, prepared with precision linear information rail, high-precision equipment rack and exquisite transmission mechanisms.

Mainly used for reducing and forming normal carbon metal plate, stainless-steel plate, aluminum and amazing steel materials.

The system is designed with small volume, open workbench and structural stability. The principle body of the system adopts the casting mattress technique, which has greater machining accuracy, greater seismic resistance and higher balance.

Product Description

The fundamental physique of the system adopts the welding mattress way, which has excessive mechanical strength, as a substitute quick manufacturing cycle, handy to set up manufacturing and minimize thermal sensitivity .

The laser adopts global superior era The special decreasing way database can raise out extraordinarily right smart decreasing for extremely right materials, optimize the decreasing surface, reduce a miles wider kind of materials, quicker speed, higher brilliant and minimize cost, and can be carried out to the generic insurance of low-energy to immoderate-energy lasers.

The laser head can routinely keep away from boundaries. The laser head can raise out excessive dynamic response, assume boundaries in improve and shield the laser head to the best extent.

Steel beam is adopted, with excessive speed. High strength, right plasticity and toughness. Uniform material and excessive going for walks reliability.

The metallic structure has the blessings of easy manufacture, quick manufacturing cycle and right assembly. Steel beam is adopted, with excessive speed.High strength, right plasticity and toughness. Uniform material and excessive going for walks reliability.

The steel shape has the blessings of smooth manufacture, quick manufacturing cycle and right assembly.

Product Specifications

| Model | 12D | 16D | 20D | 25D | 30D |

| Work Processing Area | 12500mm*3200mm | 16500mm*3200mm | 20500mm*3200mm | 25000mm*4500mm | 30000mm*6000mm |

| Laser Sources Power | 6000/12000/15000/20000/30000/40000W | ||||

| Position Accuracy | 0.1mm | ||||

| Repeatability Accuracy | 0.08mm | ||||

| X-Y Simultaneous Speed | 80m/min | ||||

| X-Y Simultaneous Acceleration | 1G | ||||

Packing Of Steel Plate Laser Cutting Machine Sheet Metal Iron :

| Function¶meter List | 24D | 20D | 16D | 12D | ||

| ●standard configuration, | ||||||

| ○optional configuration, | ||||||

| ×No configuration required | ||||||

| Item | Subitem | |||||

| Basic parameter | Working area | 24500mm*3200mm | 20500mm*3200mm | 16500mm*3200mm | 12500mm*3200mm | |

| Max.linkage speed | 50m/min | 50m/min | 50m/min | 50m/min | ||

| Automatic adjustment of cutting gas pressure | 6KW below:O2 | 6KW below:O2 | 6KW below:O2 | 6KW below:O2 | ||

| 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | |||

| Performance | Max.acceleration | 0.8G | 0.8G | 0.8G | 0.8G | |

| Table load bearing | 34000KG | 28000KG | 23000KG | 17000KG | ||

| Distance between rails | 4500mm | 4500mm | 4500mm | 4500mm | ||

| Configuration | Optical system | laser head | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools |

| 12KW and above:Germany Precitec/BLT | 12KW and above:Germany Precitec/BLT | 12KW and above:Germany Precitec/BLT | 12KW and above:Germany Precitec/BLT | |||

| Laser source | MAX | MAX | MAX/IPG | MAX/IPG | ||

| mechanical system | Gantry structure | High strength welding beam | High strength welding beam | High strength welding beam | High strength welding beam | |

| X-axis、Y-axis、Z-axis Servo motor and driver | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | ||

| Linear Rails | Made in Taiwan HiWin | Made in Taiwan HiWin | Made in Taiwan HiWin | Made in Taiwan HiWin | ||

| Rack | Made in Taiwan YYC | Made in Taiwan YYC | Made in Taiwan YYC | Made in Taiwan YYC | ||

| Machine bed | Segmented type rail lathe bed | Segmented type rail lathe bed | Segmented type rail lathe bed | Segmented type rail lathe bed | ||

| Enhanced-partition Dust Removal | ○ | ○ | ○ | ○ | ||

| Electrical system | Control system | FSCUT2000S | FSCUT2000S | FSCUT2000S | FSCUT2000S | |

| 8kw:FSCUT8000 | 8kw:FSCUT8000 | 8kw:FSCUT8000 | 8kw:FSCUT8000 | |||

| Electrical proportional valve | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | ||

| O2 Cutting gas control valve | Japan SMC | Japan SMC | Japan SMC | Japan SMC | ||

| N2Cutting gas control valve | 4KW and below:Japan SMC | 4KW and below:Japan SMC | 4KW and below:Japan SMC | 4KW and below:Japan SMC | ||

| 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | |||

Related News

Submitted successfully

We will contact you as soon as possible