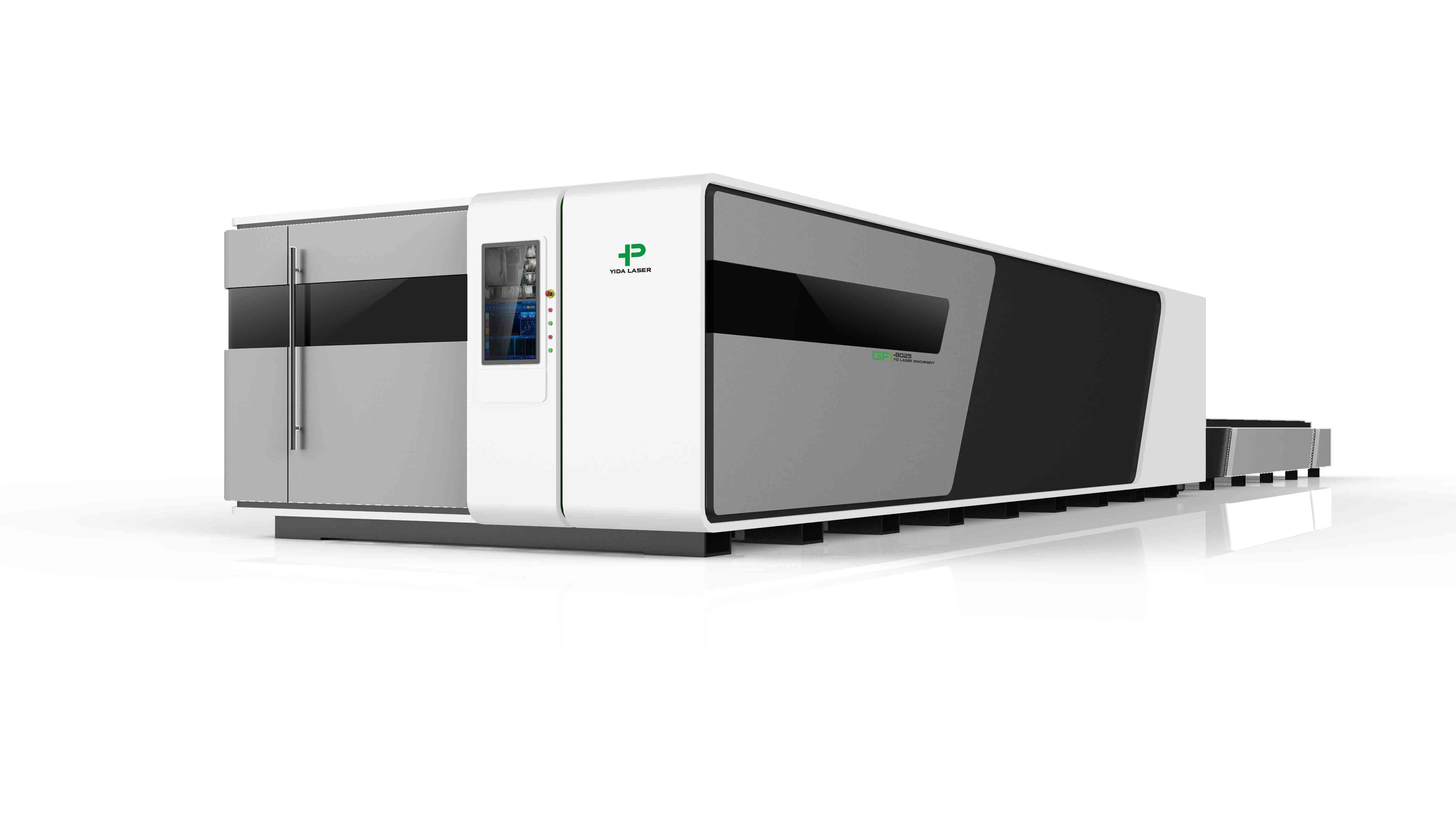

Metal Laser Cutting Machine

Fully Enclosed Body

Double Exchange Table Platform

6000W-30000 W Laser Power

High Power Metal Laser Cutter

Product Description

Laser metal cutting machine, laser cutting machine, YD laser G series high-end laser cutting machine, high-speed stability, large surrounding design, 10000 watts of ultra-high power.

It is shaped like a mountain with heaven and earth inside

The main body of the equipment adopts the casting bed process, which has higher machining accuracy, better seismic resistance and higher stability.

Parallel interactive worktable, full surrounding protection, safe operation and doubled efficiency. Zone negative pressure dust removal, clean and environment-friendly.

The laser adopts international advanced technology

The unique cutting process database can carry out different intelligent cutting for different materials, optimize the cutting surface, cut a wider range of materials, faster speed, better quality and lower cost, and can be applied to the full coverage of low-power to high-power lasers.

The laser head can automatically avoid obstacles. The laser head can carry out high dynamic response, predict obstacles in advance and protect the laser head to the greatest extent.

Cast aluminum beam is fast. Aluminum alloy has the metal characteristics of light weight and strong rigidity, which is conducive to high-speed movement in the machining process, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

Product Specifications:

| Model | 3015G | 4020G | 6025G | 8025G | 12025G |

| Work Processing Area | 3050mm*1530mm | 4000mm*2000mm | 6100mm*2500mm | 8100mm*2500mm | 12000mm*2500mm |

| Laser Sources Power | 6000/12000/15000/20000/30000W | ||||

| Position Accuracy | 0.03mm | ||||

| Repeatability Accuracy | 0.02mm | ||||

| X-Y Simultaneous Speed | 140m/min | ||||

| X-Y Simultaneous Acceleration | 2G | ||||

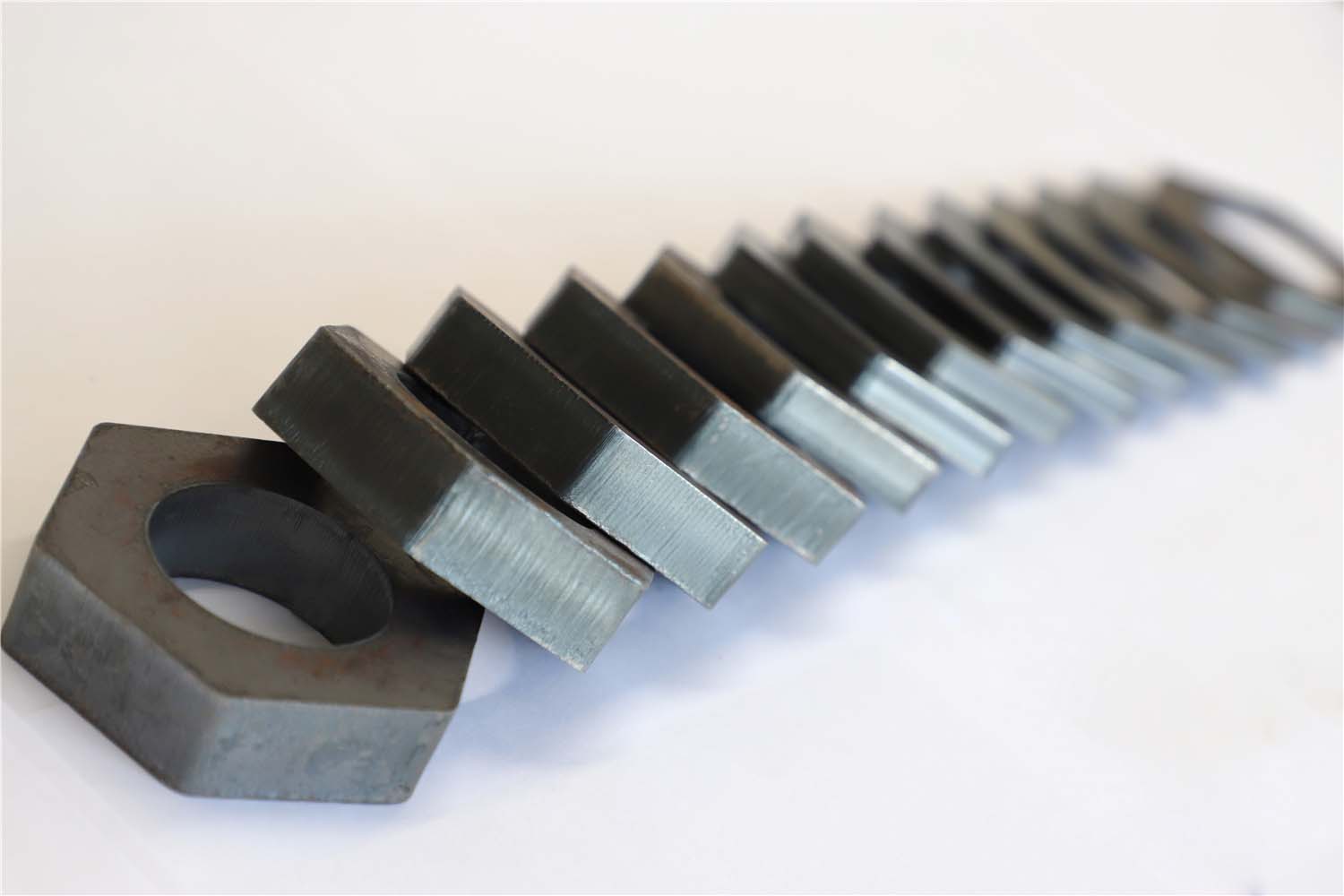

Sample :

Packing:

| Function¶meter List | 8025H | 6025H | 4020H | 3015H | ||

| ●standardconfiguration, | ||||||

| ○optional configuration, | ||||||

| ×No configuration required | ||||||

| Item | Subitem | |||||

| Basic parameter | Working area | 8000mm*2500mm | 6100mm*2500mm | 4000mm*2000mm | 3050mm*1530mm | |

| Max.linkage speed | 110m/min | 110m/min | 110m/min | 110m/min | ||

| Automatic adjustment of cutting gas pressure | 6KW below:O2 | 6KW below:O2 | 6KW below:O2 | 6KW below:O2 | ||

| 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | |||

| Performance | Max.acceleration | 1.2G | 1.2G | 1.2G | 1.2G | |

| Table load bearing | 4250kg(1-4kw) | 4050kg(1-4kw) | 3050kg(1-4kw) | 1600kg(1-4kw) | ||

| 5800kg(≥6kw) | 5300kg(≥6kw) | 4200kg(≥6kw) | 2500kg(≥6kw) | |||

| Overall weight | ≈21000kg | ≈15000kg | ≈10000kg | ≈6000kg | ||

| Configuration | Optical system | laser head | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools |

| 12KW and above:Germany Precitec/BLT | 13KW and above:Germany Precitec/BLT | 14KW and above:Germany Precitec/BLT | 15KW and above:Germany Precitec/BLT | |||

| Laser source | MAX/IPG/Raycus/GW | MAX/IPG/Raycus/GW | MAX/IPG/Raycus/GW | MAX/IPG/Raycus/GW | ||

| mechanical system | Machine bed | Welded bed | Welded bed | Welded bed | Welded bed | |

| Gantry structure | Cast Aluminum gantry | Cast Aluminum gantry | Cast Aluminum gantry | Cast Aluminum gantry | ||

| X-axis、Y-axis、Z-axis Servo motor and driver | Japan Fuji/France Schneider | Japan Fuji/France Schneider | Japan Fuji/France Schneider | Japan Fuji/France Schneider | ||

| Linear Rails | Made in Taiwan HiWin | Made in Taiwan HiWin | Made in Taiwan HiWin | Made in Taiwan HiWin | ||

| Rack | Made in Taiwan YYC | Made in Taiwan YYC | Made in Taiwan YYC | Made in Taiwan YYC | ||

| Protective Enclosure | ● | ● | ● | ● | ||

| Enhanced-partition Dust Removal | ● | ● | ● | ● | ||

| Electrical system | Control system | FSCUT2000S | FSCUT2000S | FSCUT2000S | FSCUT2000S | |

| 8kw:FSCUT8000 | 8kw:FSCUT8000 | 8kw:FSCUT8000 | 8kw:FSCUT8000 | |||

| Electrical proportional valve | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | ||

| O2Cutting gas control valve | Japan SMC | Japan SMC | Japan SMC | Japan SMC | ||

| N2Cutting gas control valve | 4KW and below:Japan SMC | 4KW and below:Japan SMC | 4KW and below:Japan SMC | 4KW and below:Japan SMC | ||

| 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | |||

Related News

Submitted successfully

We will contact you as soon as possible