D-Cheap Price Laser Cutting Machine Manufacturers Europe

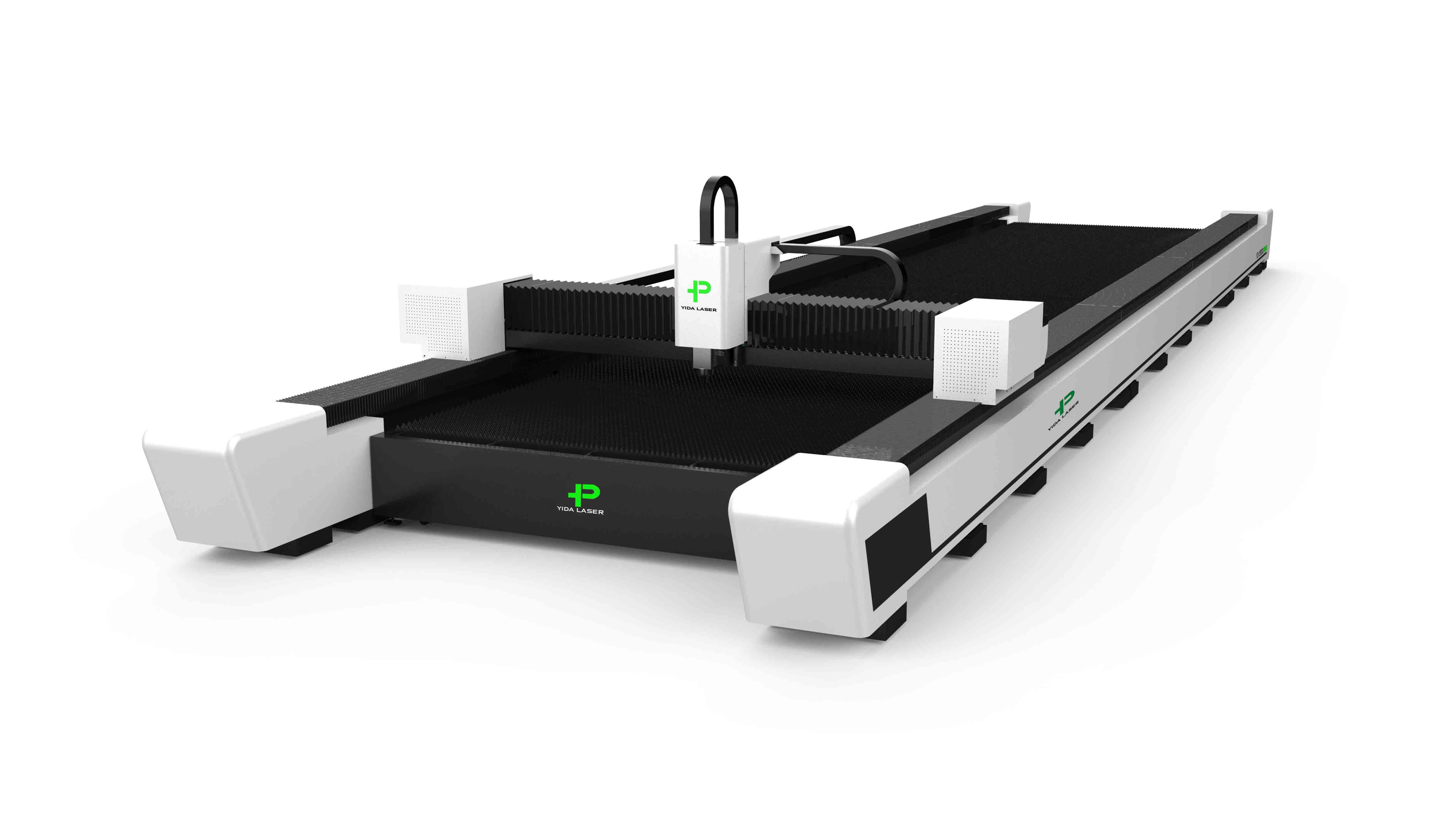

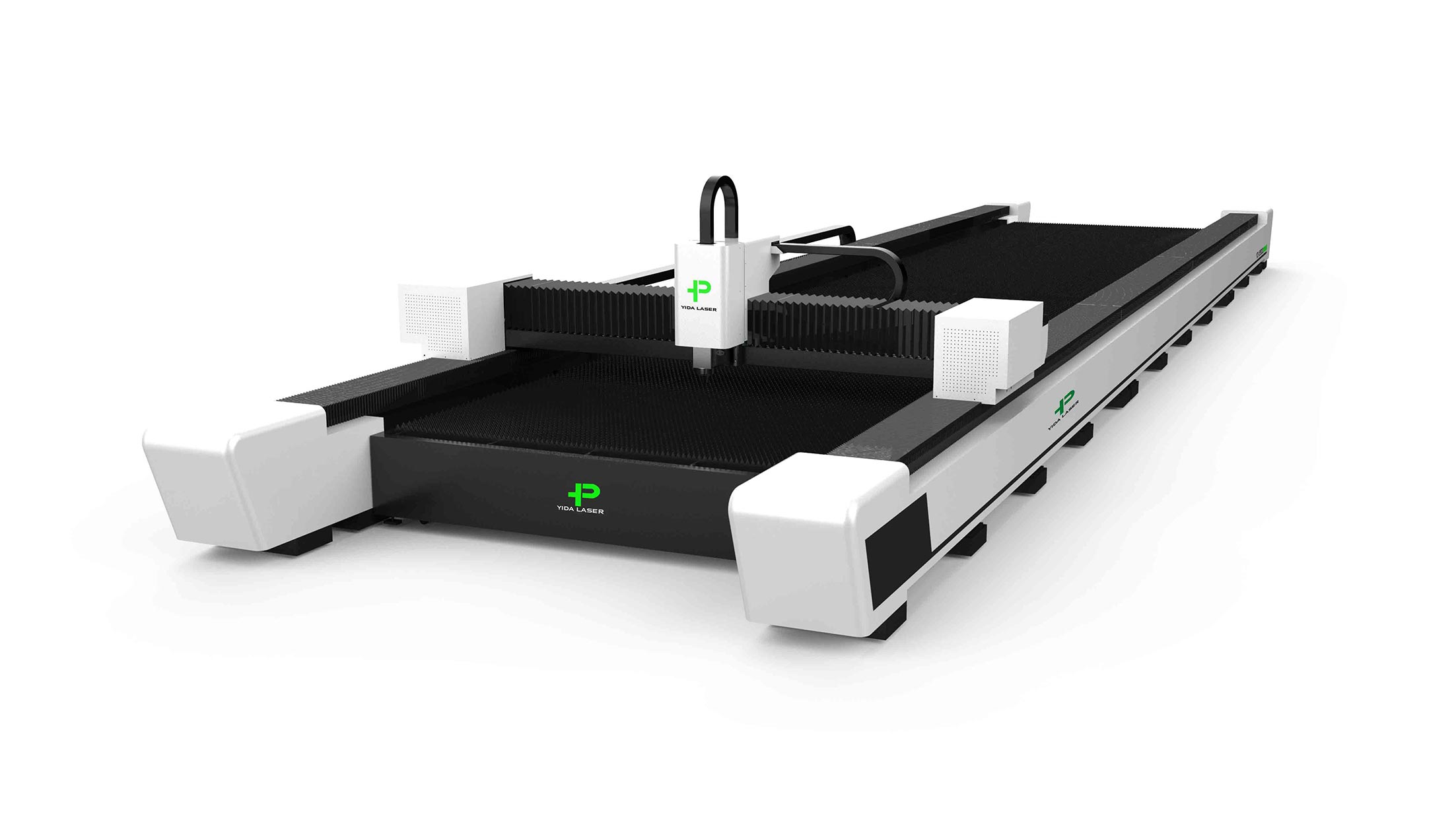

YD Laser D Series Super Large Format Laser Cutting Machine

Adopts excessive-power fiber laser, organized with precision linear guide rail, high-precision tools rack and extraordinary transmission mechanisms.

Mainly used for cutting and forming regular carbon steel plate, stainless-steel plate, aluminum and extraordinary metallic materials.

The gadget is designed with small volume, open workbench and structural stability. The precept frame of the device adopts the casting mattress technique, which has higher machining accuracy, higher seismic resistance and better balance.

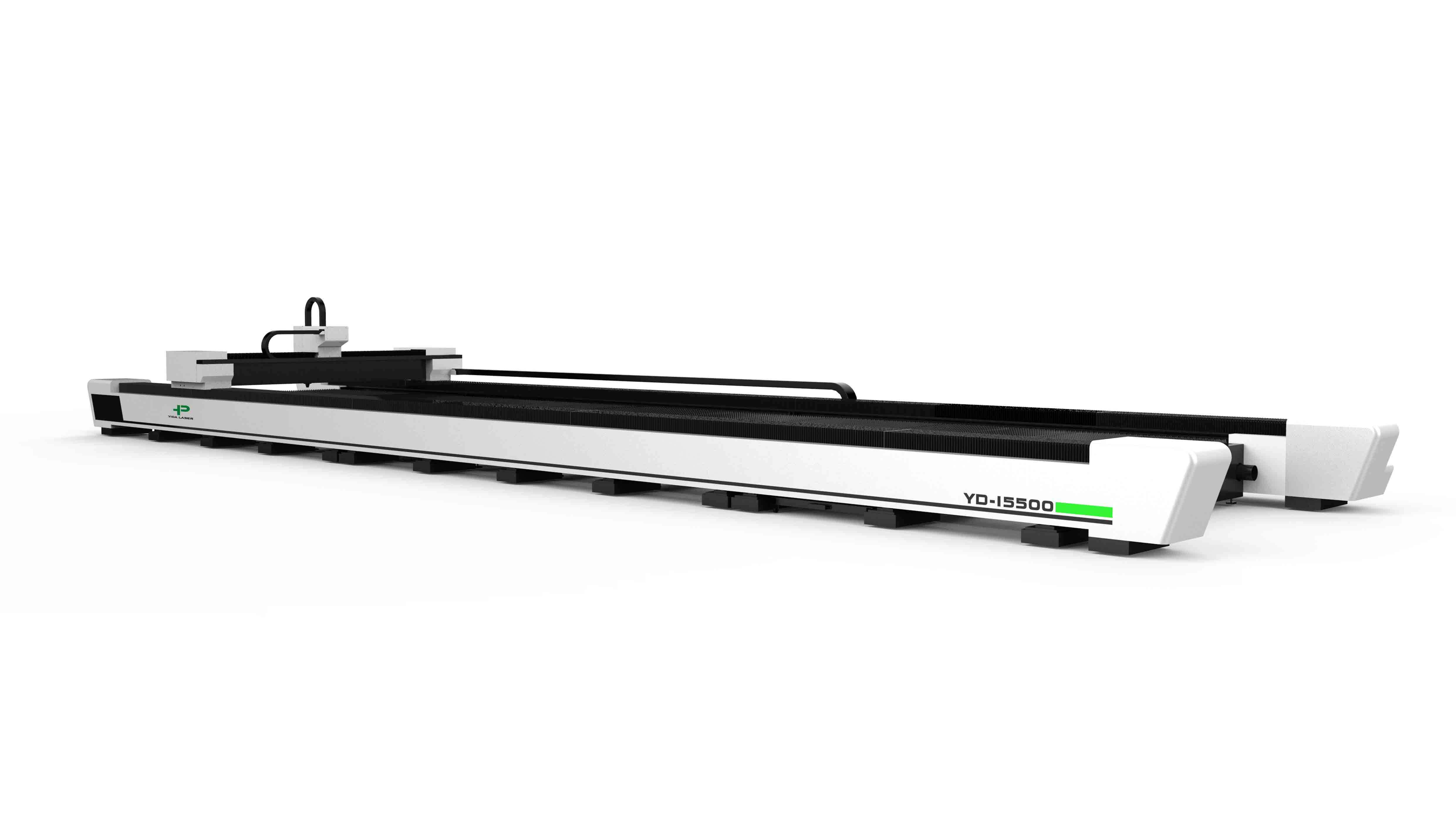

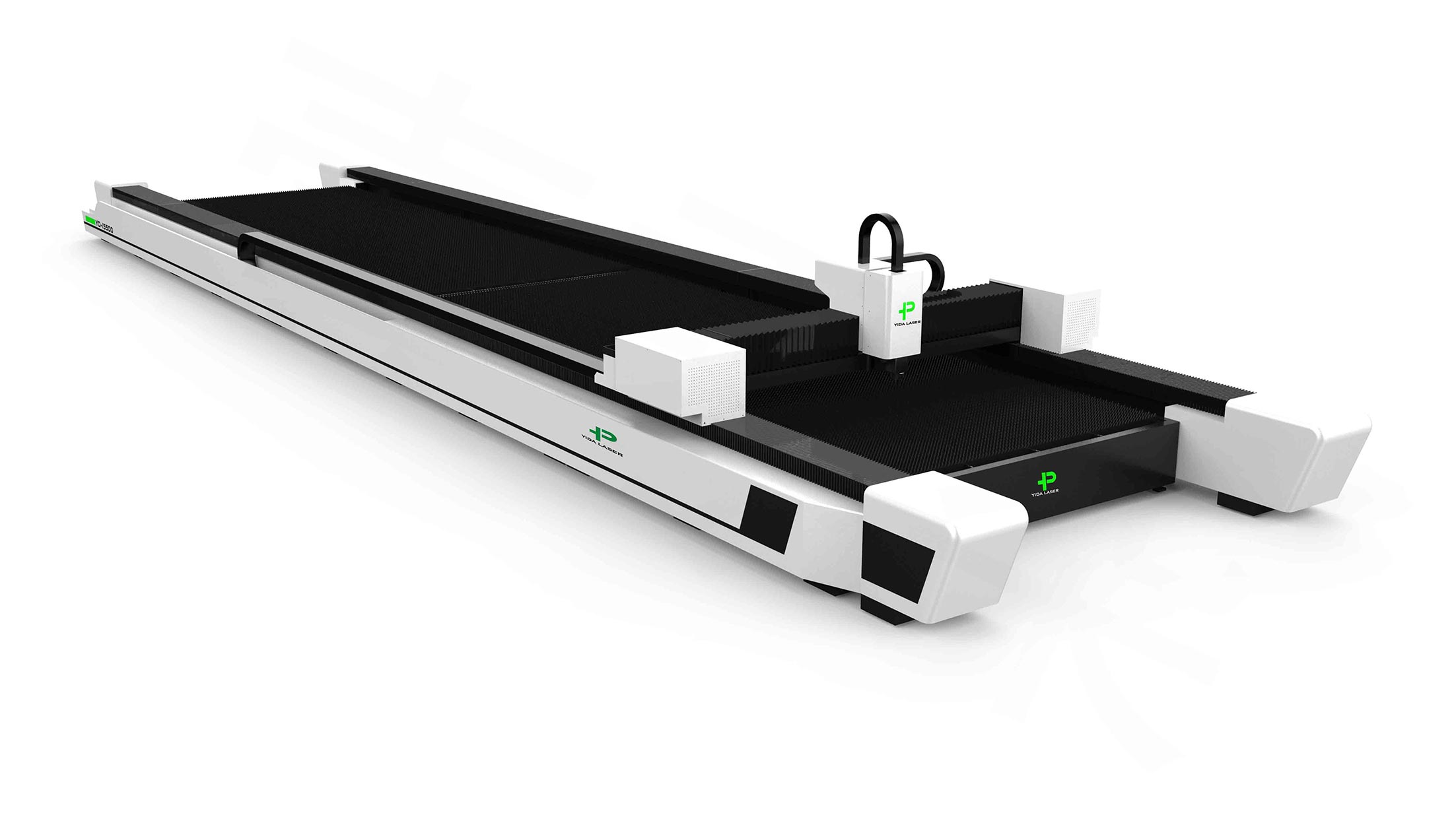

When the industry's requirements for the format of lowering machines are constantly improving, YD laser wonderful massive format D series models are born. This model enables the customization of wonderful massive format and wonderful prolonged fuselage, can area pretty some plates and has a massive sort of processing materials. Intelligent processing, there can be no need to replace the plate halfway, for you to beautify the artwork efficiency. Truly achieve "personal customization"!

The vital body of the device adopts the welding bed way, which has immoderate mechanical strength, rather short production cycle, easy to set up production and reduce thermal sensitivity The laser adopts international advanced generation The unique lowering way database can carry out extremely good clever lowering for extremely good materials, optimize the lowering surface, lessen a miles wider sort of materials, faster speed, better great and reduce cost, and can be performed to the general coverage of low-energy to immoderate-energy lasers. The laser head can automatically avoid boundaries. The laser head can carry out immoderate dynamic response, anticipate boundaries in advance and defend the laser head to the nice extent. Steel beam is adopted, with immoderate speed. High strength, correct plasticity and toughness. Uniform fabric and immoderate going for walks reliability. The metal form has the advantages of clean manufacture, short manufacturing cycle and correct assembly. Steel beam is adopted, with immoderate speed. High strength, correct plasticity and toughness. Uniform fabric and immoderate going for walks reliability. The metal form has the advantages of clean manufacture, short manufacturing cycle and correct assembly.

The laser adopts worldwide superior technology

The specific slicing procedure database can perform distinctive sensible slicing for distinctive materials, optimize the slicing surface, reduce a much wider variety of materials, quicker velocity, higher great and decrease cost, and may be carried out to the whole insurance of low-strength to excessive-strength lasers. The laser head can mechanically keep away from boundaries. The laser head can perform excessive dynamic response, expect boundaries earlier and defend the laser head to the finest extent. Cast aluminum beam is fast. Aluminum alloy has the metallic traits of mild weight and robust rigidity, that's conducive to excessive-velocity motion withinside the machining procedure, and excessive flexibility is conducive to excessive-velocity slicing of numerous photographs on the idea of excessive precision.

Product Specifications

| Model | 12D | 16D | 20D | 25D | 30D |

| Work Processing Area | 12500mm*3200mm | 16500mm*3200mm | 20500mm*3200mm | 25000mm*4500mm | 30000mm*6000mm |

| Laser Sources Power | 6000/12000/15000/20000/30000/40000W | ||||

| Position Accuracy | 0.1mm | ||||

| Repeatability Accuracy | 0.08mm | ||||

| X-Y Simultaneous Speed | 80m/min | ||||

| X-Y Simultaneous Acceleration | 1G | ||||

Packing:

Our Group:

Shandong Yida Laser Technology Co., Ltd. is a modern manufacturing enterprise specializing in the R & D and production of laser cutting machines. The company was established in 2012 and is located in Zichuan, one of the top 100 industrial areas in China.

It is the first batch of high-tech enterprises introduced from Qilu laser Industrial Park. The company has a 30000 square meter standardized plant. It has a professional technical team and operation system. The team is formed by a group of experts and professors, and at the same time, maintains a good relationship with major universities and optical research institutes in order to cooperate especially in technology exchange related to Laser cutting industry.

Since its establishment, the business enterprise has targeted at the optimization and integration of technology, fine, application, marketplace and different resources. The laser slicing gadget guided by "excessive efficiency, excessive overall performance and excessive precision" is broadly used in mechanical device, electric device, marketing and marketing signs, sheet metallic production, precision parts, virtual products, craft gifts, hardware manufacturing, digital components

automobile, steel, shipbuilding, machinery, aerospace, countrywide protection and rail transportation. Yida laser specializes in large, medium and small layout laser slicing machines. Closely following the global frontier and in near cooperation with world-well-known laser assisting providers consisting of the United States, Japan, Germany, Switzerland and United Kingdom, the evolved laser device has excessive photoelectric conversion rate, suitable beam fine and strong overall performance. In particular, the solid-kingdom laser slicing gadget occupies a main function in Asia in phrases of slicing thickness and slicing speed.

Our Factory:

Certificates:

Contact Us:

Jinan Yida Machine Tool Co., Ltd

Address: Room J1 304, high tech Wanda office building, Jinan area, Shandong pilot Free Trade Zone, China

Tel: +8653182899697

Email: yd@yd-laser.com

| Function¶meter List | 24D | 20D | 16D | 12D | ||

| ●standard configuration, | ||||||

| ○optional configuration, | ||||||

| ×No configuration required | ||||||

| Item | Subitem | |||||

| Basic parameter | Working area | 24500mm*3200mm | 20500mm*3200mm | 16500mm*3200mm | 12500mm*3200mm | |

| Max.linkage speed | 50m/min | 50m/min | 50m/min | 50m/min | ||

| Automatic adjustment of cutting gas pressure | 6KW below:O2 | 6KW below:O2 | 6KW below:O2 | 6KW below:O2 | ||

| 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | 6KW and above:O2、N2、air | |||

| Performance | Max.acceleration | 0.8G | 0.8G | 0.8G | 0.8G | |

| Table load bearing | 34000KG | 28000KG | 23000KG | 17000KG | ||

| Distance between rails | 4500mm | 4500mm | 4500mm | 4500mm | ||

| Configuration | Optical system | laser head | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools | 12KW and below:BLT/Ray Tools |

| 12KW and above:Germany Precitec/BLT | 12KW and above:Germany Precitec/BLT | 12KW and above:Germany Precitec/BLT | 12KW and above:Germany Precitec/BLT | |||

| Laser source | MAX | MAX | MAX/IPG | MAX/IPG | ||

| mechanical system | Gantry structure | High strength welding beam | High strength welding beam | High strength welding beam | High strength welding beam | |

| X-axis、Y-axis、Z-axis Servo motor and driver | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | Japan Yaskawa | ||

| Linear Rails | Made in Taiwan HiWin | Made in Taiwan HiWin | Made in Taiwan HiWin | Made in Taiwan HiWin | ||

| Rack | Made in Taiwan YYC | Made in Taiwan YYC | Made in Taiwan YYC | Made in Taiwan YYC | ||

| Machine bed | Segmented type rail lathe bed | Segmented type rail lathe bed | Segmented type rail lathe bed | Segmented type rail lathe bed | ||

| Enhanced-partition Dust Removal | ○ | ○ | ○ | ○ | ||

| Electrical system | Control system | FSCUT2000S | FSCUT2000S | FSCUT2000S | FSCUT2000S | |

| 8kw:FSCUT8000 | 8kw:FSCUT8000 | 8kw:FSCUT8000 | 8kw:FSCUT8000 | |||

| Electrical proportional valve | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | Japan SMC/Germany AVENTICS | ||

| O2 Cutting gas control valve | Japan SMC | Japan SMC | Japan SMC | Japan SMC | ||

| N2Cutting gas control valve | 4KW and below:Japan SMC | 4KW and below:Japan SMC | 4KW and below:Japan SMC | 4KW and below:Japan SMC | ||

| 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | 6KW and above:Germany AVENTICS | |||

Related News

Submitted successfully

We will contact you as soon as possible