How Does The Nozzle Affect The Quality Of Laser Cutting?

How Does The Nozzle Affect The Quality Of laser Cutting?

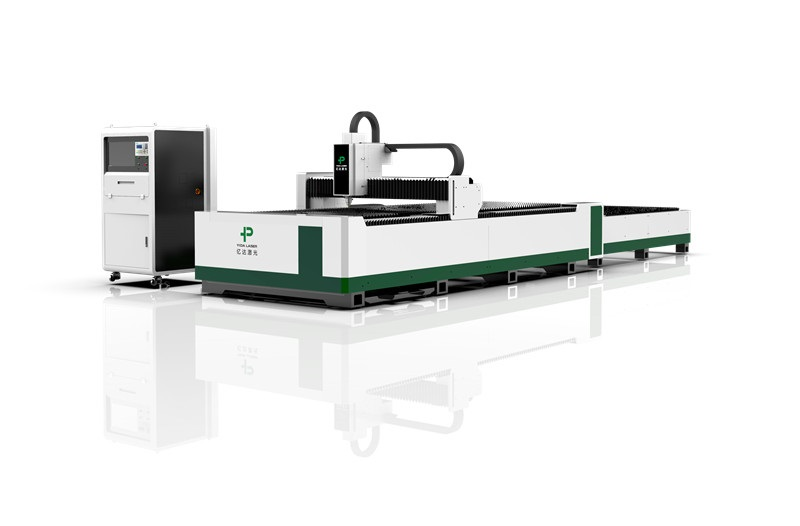

In the field of Laser Cutting industry, the fiber laser cutting machine is the main equipment, and the cutting process is carried out by emitting laser beams. In this process, the nozzle is a component that cannot be ignored. Although the nozzle is inconspicuous, it plays an important role. It is responsible for keeping the distance between the laser head and the workpiece, guiding the auxiliary gas to pass through the workpiece to be cut smoothly, and forming high pressure at the nozzle outlet to speed up the cutting speed, take away the slag, and protect the internal lens of the laser head. The choice of nozzle directly determines the quality of laser cutting.

If the nozzle is not in the same axis as the laser, the cutting quality will be affected as follows.

(1) Influence on the cutting surface When the auxiliary gas is blown out from the nozzle, the gas volume is uneven, and there is a phenomenon that there is a melt on one side but not on the other side. It has little impact on cutting thin plates below 3mm, and has serious impact on cutting over 3mm, sometimes it cannot cut through.

(2) Influence on sharp corners

When the workpiece has sharp corners or small angles, over-melting is easy to occur, and thick plates may not be cut.

(3) Effect on perforation

The piercing is unstable, the time is not easy to control, it will cause over-melting to the thick plate, and the piercing conditions are not easy to grasp. Little effect on thin plates.

The adjustment method of the coaxiality between the nozzle and the laser beam:

(1) Paste scotch tape on the nozzle opening, and a circular mark of the nozzle opening will be left on the tape.

(2) With a power of about 300W, the laser will shoot through the tape and leave a small hole.

(3) Remove the scotch tape and observe the relative position of the small hole and the circle.

What should I do if the nozzle is hot?

1. Check whether the chiller equipment is turned on, and turn on the chiller;

2. Check whether the focusing optical path is correct, and adjust the focusing optical path;

3. Check whether the nozzle is blocked and clean the nozzle;

4. Avoid long-term continuous work, and let the equipment cool down regularly.

To sum up, choosing a suitable nozzle has a decisive impact on the cutting quality of fiber laser cutting machine. \

We should choose an appropriate nozzle aperture according to the material and thickness of the workpiece; at the same time, we should maintain the nozzle regularly to avoid its heating phenomenon and ensure the stability of laser cutting.