How Does A Laser Cutter Work?

Laser Cutting Principle

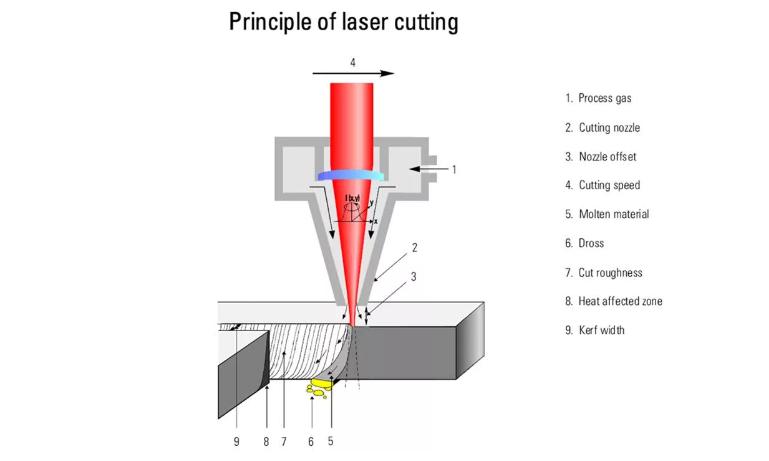

Laser cutting replaces mechanical knives with invisible lasers. It has the traits of excessive precision, quick cutting, no longer restrained to cutting patterns, computerized typesetting to retailer materials, clean incision, low processing cost, inexperienced and pollution-free, etc. Let's take a nearer appear at the precept of Laser Cutting.

Laser cutting is done through excessive energy density power generated via laser focusing. Under the manipulate of the computer, the laser is discharged via the pulse to output the managed repetitive high-frequency pulse laser to shape a beam with a positive frequency and a positive pulse width. The pulse laser beam is transmitted and mirrored via the optical direction and centered on the floor of the processed object, tiny, high-energy-density mild spots are formed, melting or vaporizing the processed fabric at an immediate excessive temperature.

Each high-energy laser pulse right away sputters a small gap on the floor of the object. Under the manage of the computer, the laser processing head and the cloth to be processed function non-stop relative movement in accordance to the pre-drawn graphics, so that the object will be processed to the favored shapes.

The laser cutter focuses the laser mild on the material, heats the cloth phase till it exceeds the melting point, and then blows the molten metallic away with the coaxial high-pressure gasoline or the generated metallic vapor pressure, as the mild beam strikes surprisingly linearly with the material, the holes are always shaped into a slim slit.

The power will be launched when the laser beam irradiates the floor of the steel sheet. And the electricity will soften the metallic sheet, and the slag will be blown away by using the gas. Through the lens and mirror, the laser beam is targeted in a small area. The excessive awareness of strength motives the neighborhood place to be heated rapidly, inflicting the sheet metallic to melt.

In addition, due to the fact the laser emission electricity is very concentrated, solely a small quantity of warmness is transferred to different components of the metallic sheet, so there is little deformation of the material. However, the use of laser can additionally reduce the blanks of complicated shapes very accurately, and the reduce blanks do now not want similarly processing.

Operating steps

1. Firstly, repair the cloth to be reduce on the working desk of the laser cutter.

2. Then modify the tools parameters in accordance to the fabric and thickness of the metallic sheet.

3. Then choose the excellent lens and nozzle, and take a look at it earlier than beginning the machine, you want to test whether or not it is intact and clean.

4. Then modify the cutting head to the fantastic focal point function in accordance to the cutting thickness and cutting requirements.

5. Select the excellent cutting fuel and test whether or not the gasoline ejection nation is regular and good.

6. Try to reduce the material. After the cutting process, Check whether or not the reduce floor is vertical and difficult and whether or not there are burrs and dross.

7. Analyze the cutting floor and alter the cutting parameters therefore till the cutting floor of the pattern meets the standard.

8. Carry out the programming of the workpiece drawing and the typesetting of the entire board cutting, and then import it into the cutting software program system.

9. Adjust the cutting head and focal length, put together auxiliary gasoline and begin cutting.

10. Finally, test the sample. If there is any problem, regulate the parameters in time till the cutting meets the method requirements.

Cutting accuracy is the first aspect to choose the fantastic of CNC laser cutting machines. Four elements have an effect on the cutting accuracy of CNC laser cutting machines.

1. The measurement of the laser condensation of the laser generator. If the mild spot is very small after gathering, the cutting precision is very high, and if the hole after cutting is additionally very small, it suggests that the precision of the laser cutting computing device is even an awful lot higher, and the satisfactory is very high. However, the beam emitted by means of the laser is cone-shaped, so the slits reduce out are additionally cone-shaped. Under this condition, the higher the thickness of the workpiece, the lower the accuracy, so the large the kerf.

2. The precision of the workbench. If the precision of the workbench is very high, the precision of cutting will additionally be improved. Therefore, the accuracy of the workbench is additionally a very essential element to measure the accuracy of the laser generator.

3. The laser beam is condensed into a cone shape. When cutting, the laser beam is conical downward. At that time, if the thickness of the reduce workpiece is very large, the cutting precision will be reduced, and the reduce hole will be very large.

4. The sorts of cutting substances will additionally have an effect on the accuracy of the laser cutter. Under the equal circumstances, the precision of cutting stainless metal and cutting aluminum will be very different, the cutting precision of stainless metal will be higher, and the cutting floor will be smoother.

If you favor to recognize extra information and recommendations about laser cutter, we will be your answerer.

If you are thinking about shopping for a first-rate laser cutter, we will be your better choice.