High Power Laser Cutting: Common Problems Effective Solutions

Troubleshooting High Power Laser Cutting: Common Problems and Effective Solutions

With inimitable blessings comparable to thick steel sheet ability, presto cutting speed, and functionality to reduce thicker plates, high-power fiber laser cutting has been notably honored by means of the request. still, due to the fact high-power fiber laser technological know-how is nonetheless in the unique stage of popularization, some operators are not usually professed in high-power fiber laser chops.

The high-power fiber laser computing device technician of Golden Laser has delivered up a collection of consequences to high-power fiber laser cutting issues thru long-term checking out and exploration, for reference by using all buddies in the assiduity.

Firstly, the following motives must be checked first ,If the cutting impact is set up to be poor.

1. All lenses in the laser head are easy and free of pollution;

2. The water temperature of the water tank is normal, and the laser has no condensation;

3. The chastity of the laser cutting fuel is excellent, the gasoline route is smooth, and there is no fuel leakage.

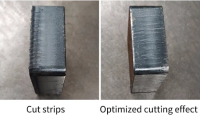

Question 1 Cut strips

Possible Causes

1. The snoot choice is wrong and the snoot is too large;

2. The air strain placing is incorrect, and the air strain is set too high, performing in stripes after overheating;

3. The laser cutting velocity is wrong, too sluggish or too presto will beget full overheating.

Solution:

1. To substitute the nozzle, change the nozzle with a small periphery.

For illustration, for a sixteen mm carbon sword vibrant face slice, you can select high-speed nozzle D1.4 mm; for a 20 mm carbon sword vivid face, you can select high-speed contact nozzle D1.6 mm;

2. Reduce the air stress and ameliorate the cutting pleasant of the quit face;

3. Acclimate the laser cutting speed. Only when the strength fits the cutting pace duly can the impact proven on the proper as proven under be achieved.

laser reduce strips solution

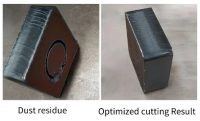

Problem two There's dirt residue at the bottom

Possible Causes:

1. The nozzle determination is too small, and the laser center of attention would not match;

2. The air stress is too low or too high, and the laser cutting pace is too fast;

3. The cloth of the steel sheet is poor, the first-rate of the board is not good, and it is refined to dispose of the dirt residue with a small nozzle.

Solution:

1. Replace the large-periphery nozzle and acclimate the center of attention to a appropriate position;

2. Increase or drop the air strain till the air influx is applicable;

3. Choose a appropriate steel plate.

dust residue

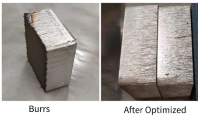

Problem three There are burrs at the bottom

Possible Causes:

1. The nozzle periphery is too small to meet the processing conditions;

2. still, you have to extend the poor defocus and acclimate the ideal role If the terrible defocus does not match.

3. The air strain is too small, performing in burrs on the bottom, which can now not be totally cut.

Solution:

1. Choose a large- periphery nozzle to make bigger the air inflow;

2. Increase the terrible defocus to make the laser beam area attain the nethermost position;

3. including the air stress can limit the backside burrs.

burrs solution

If you have any questions or top suggestions, welcome to contact us for similarly discussion.